The two-axis shredder, also known as the shear shredder, reduces the size of the material by cutting, tearing and extruding. SX series shredder produced by our company is after many years of research and practice, and according to the actual situation in China to improve research and development, the introduction of mature technology and excellent design of the two-axis shredder series, for China's waste recycling in the early stage of crushing, capacity reduction treatment to provide good quality equipment.

1. The two-axis shredder has low speed, high torque, low noise and other characteristics, using PLC control system, can be automatically controlled, with start, stop, reverse and overload automatic reverse control function.

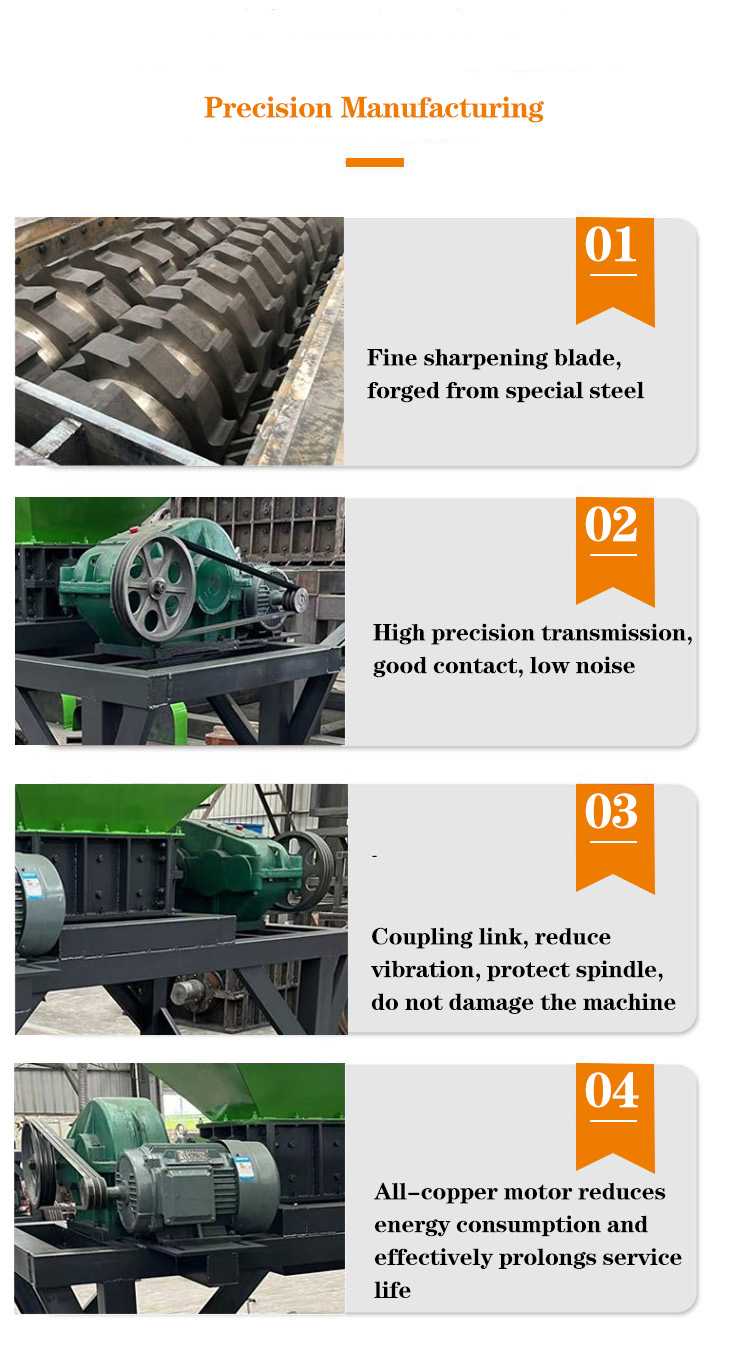

2. The motor + reducer drives the cutter shaft to achieve the cutting effect of low speed and high torque.

3. Bearing six-fold seal, effective waterproof and dustproof, prolong the service life of the bearing.

4. After the tool is worn, the tool coating and welding repair technology is used to achieve multiple reuse of the tool and greatly reduce the maintenance cost of the tool.

5. Split box design, can easily and quickly remove the entire cutter shaft (shaft, blade, bearing, sealing system).

6. The tool is arranged according to the helix to achieve efficient cutting.

7. The inner hole and spindle face of the tool are designed with six sides to achieve the uniformity of the force of the tool.

8. According to the different materials and product shapes to tear, you can choose different types of tools.

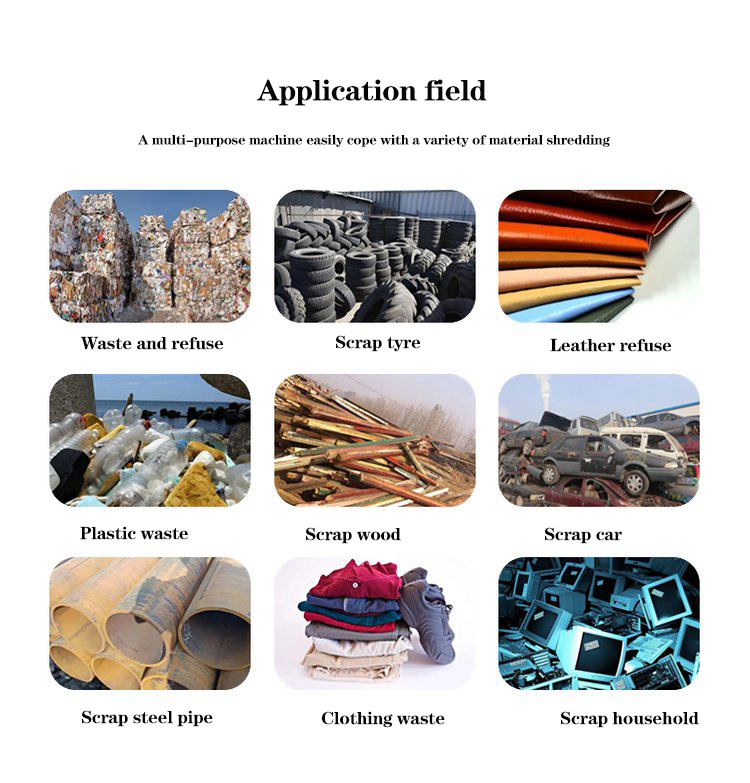

Dual shaft shredder using dual shaft independent drive, so that in the production, the material produces the corresponding pressure, to achieve the automatic feeding function, the unique tool shaft structure and rotary tool, in the production process of low speed and high torque, there will be no winding, or stuck equipment phenomenon, thereby improving the production efficiency, the equipment is suitable for a variety of toughness, high viscosity of the material crushing.

Model | Overall dimensions (L W H)(mm) | Crushing chamber size (mm) | Blade diameter (mm) | Blade thickness (mm) | Number of blades (pieces) | Power (kw) | Weight (kg) |

EH-500 | 2800×1300×1850 | 500×480 | 200 | 20 | 24 | 11×2 | 2200 |

EH-800 | 3000×1300×1850 | 800×480 | 200 | 20 | 40 | 15×2 | 2500 |

EH-1000 | 3300×1900×2200 | 1000×690 | 300 | 40 | 24 | 22×2 | 5200 |

EH-1200 | 3600×2000×2200 | 1200×690 | 300 | 40 | 30 | 30×2 | 6400 |

EH-1500 | 4180×2100×2400 | 1500×850 | 550 | 50/75 | 30/20 | 55×2 | 9000 |

EH-1800 | 5800×2400×3300 | 1800×1206 | 550 | 50/75 | 36/24 | 75×2 | 13600 |

EH-2000 | 6400×2700×3500 | 2000×1490 | 600 | 50/75 | 40/26 | 90×2 | 20100 |

EH-2500 | 7500×3200×3800 | 2500×1800 | 600 | 75/100 | 32/24 | 110×2 | 25000 |

EH-3000 | 8600×3500×4000 | 3000×1800 | 600 | 75/100 | 40/30 | 160×2 | 31000 |

Remark:1.The number, diameter and thickness of blade claws can be customized according to the type of material and discharge size; 2. Different types of materials and discharge sizes, equipment output will be differen | |||||||