Paint barrel shredder is a new type of energy-saving and environmentally friendly shredding equipment for shredding metal such as paint barrels and recycling metal materials to achieve the recycling of resources; It also combines all the advantages of the crusher, is an advanced crushing equipment. The biggest advantage of the paint drum shredder is that it can maximize meet the basic requirements of the electric furnace steelmaking for concentrate steelmaking and shorten the smelting time, and the pure torn steel can also be used as the addition of the converter steelmaking.

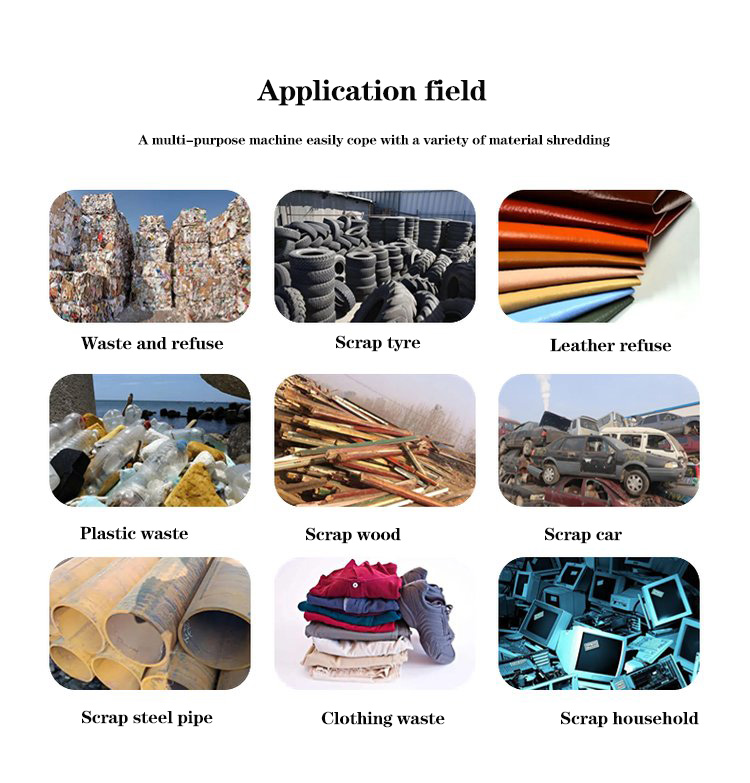

1. The paint bucket shredder is easier to tear than the single-axis shredder, which is better and more efficient for some relatively large materials such as large plastics, rubber tires, fibers, TV sets, door panels and so on.

2. Two-axis shearing is more suitable for some framed materials.

3. Safety signs and safety labels to ensure safe use;

4. Can be equipped with conveyor belt feeding.

The paint drum shredder uses the basic principle of hammer hitting, the feeding port is equipped with a filter conveyor belt, driven by the high-speed high-torque motor, the hammer head on the main engine rotor takes turns to hit the objects to be broken into the chamber, and tears the objects to be broken into the specifications through the space formed between the lining plate and the hammer head. According to the working condition of the crusher, it can be divided into dry system, wet system and semi-wet system. The dry system mainly refers to the broken material must pass through the air rotation sorting system to separate the metal and non-metal, and the whole system is equipped with a dust removal device. The wet system means that water is sprayed at the same time of crushing, and water is washed at the same time of sorting.

Model | Overall dimensions (L W H)(mm) | Crushing chamber size (mm) | Blade diameter (mm) | Blade thickness (mm) | Number of blades (pieces) | Power (kw) | Weight (kg) |

EH-500 | 2800×1300×1850 | 500×480 | 200 | 20 | 24 | 11×2 | 2200 |

EH-800 | 3000×1300×1850 | 800×480 | 200 | 20 | 40 | 15×2 | 2500 |

EH-1000 | 3300×1900×2200 | 1000×690 | 300 | 40 | 24 | 22×2 | 5200 |

EH-1200 | 3600×2000×2200 | 1200×690 | 300 | 40 | 30 | 30×2 | 6400 |

EH-1500 | 4180×2100×2400 | 1500×850 | 550 | 50/75 | 30/20 | 55×2 | 9000 |

EH-1800 | 5800×2400×3300 | 1800×1206 | 550 | 50/75 | 36/24 | 75×2 | 13600 |

EH-2000 | 6400×2700×3500 | 2000×1490 | 600 | 50/75 | 40/26 | 90×2 | 20100 |

EH-2500 | 7500×3200×3800 | 2500×1800 | 600 | 75/100 | 32/24 | 110×2 | 25000 |

EH-3000 | 8600×3500×4000 | 3000×1800 | 600 | 75/100 | 40/30 | 160×2 | 31000 |

Remark:1.The number, diameter and thickness of blade claws can be customized according to the type of material and discharge size; 2. Different types of materials and discharge sizes, equipment output will be differen | |||||||